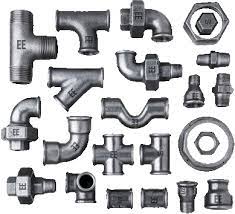

Butt Weld Fittings, Threaded Black & Galvanized Malleable Iron Fittings, Forged Steel Fittings, Stainless Steel Welded & Threaded Fittings, Copper Fittings, Grooved Fittings.

A buttweld fitting is a weldable pipe fitting that allows for change of direction of

flow,

to branch off, reduce pipe size or attach auxiliary equipment

Butt weld

fittings SCH.40 & SCH.80

SPEC: ANSI B16.9 , ANSI B16.28

BRAND & ORIGIN : Benkan Japan & Thailand, Korea & China

Black steel pipe fittings and galvanized steel pipe fittings are the two most common kind

of

pipe applied to transport liquid and gas. Both black steel pipe and galvanized pipe are

made of steel, however,

galvanized pipe has a zinc coating while black pipe does not. As a result galvanized

pipe is more durable.

Threaded fittings black & galv.malliable iron

SPEC: Class 150LBS – ANSI B2.1, BS 21 & DIN 2999

BRAND & ORIGIN : Hitachi – Japan

Forged steel fittings are pipe fittings that are made from forged carbon steel material.

Forging steel is a process that creates very strong fittings. Carbon steel is heated to

molten temperatures and placed in the dies. The heated steel is then machined into the

forged steel fittings

SOCKET – weld & threaded

SPEC: ANSI B16.11, A 105

ORIGIN : Italy & Taiwan

Threaded piping is commonly used in low-cost, noncritical applications such as domestic

water, fire protection, and industrial cooling water systems.

Threaded fittings are normally made of cast gray or malleable iron, cast brass or

bronze, or forged alloy and carbon steel.

SPEC: ANSI B16.9 Welded & Class 150

Threaded

ORIGIN: Taiwan, Singapore & Japan

These fittings are used for installation of various types of pipes. In fact, copper

pipe fittings are mainly used with copper pipes used for supplying hot and cold water in

residential water supply lines, as refrigerant line in HVAC, etc.

SPECS :

ASTM & BS Standard

BRAND & ORIGIN : Nibco, Mueller –USA & UK

Grooved pipe couplings and fittings are used to join pipes in both wet and dry system

. They provided some flexibility in terms of movement and deflection to the piping

system.

The concept of grooved coupling was invented in 1925 when Victaulic designed the first

mechanical coupling.