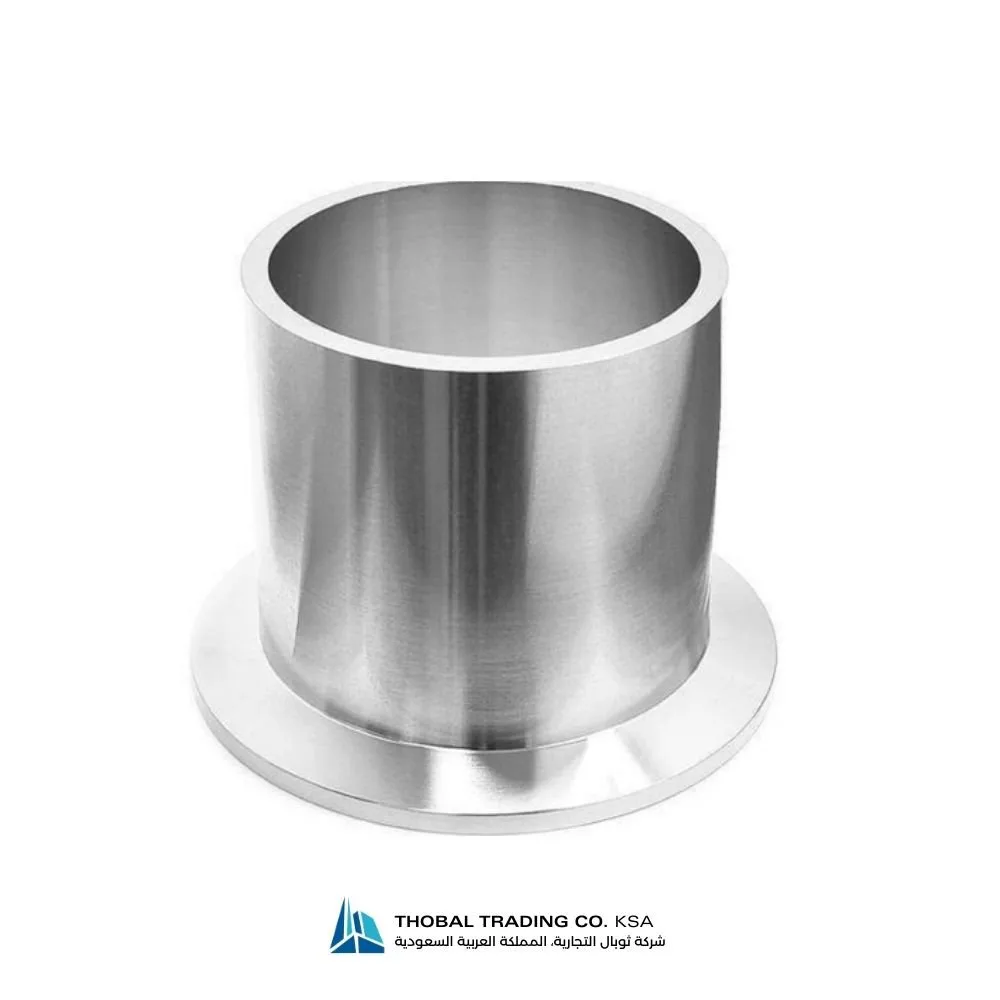

Product Overview

The Hygienic Stub End is the essential bridge between modular flanged connections and high-purity process tubing. Unlike industrial schedule stub ends, these are precision-sized to match the Outer Diameter (OD) of sanitary tubes, ensuring a perfectly flush internal transition that satisfies the most stringent hygiene requirements.

Rotatable Flange Flexibility

[Image showing a hygienic stub end paired with a loose lap joint flange] When paired with a Lap Joint (Backing) flange, the stub end allows for 360-degree rotation of the bolt holes. This is a critical advantage in complex hygienic manifolds where precise alignment of fixed flanged equipment—such as pumps, tanks, or large valves—is required. Because the flange does not touch the process media, the stub end maintains the aseptic integrity of the system.

Aseptic Surface Engineering

Surface chemistry is paramount in hygienic environments. Our stub ends are mechanically polished to a mirror finish (Ra < 0.6μm), eliminating microscopic harbor points where bacteria could thrive. This high-purity finish ensures that Clean-in-Place (CIP) and Steam-in-Place (SIP) cycles are completely effective, maintaining the safety of your product batch.

Global Hygienic Standard Compliance

We offer stub ends that align with the engineering codes utilized in high-purity industries worldwide:

-

SMS & ISO: The standard choice for liquid food and beverage distribution headers.

-

DIN 11850: Common in European pharmaceutical and high-end chemical process skids.

-

ASTM A270: American standard for seamless and welded austenitic stainless steel sanitary tubing fittings.