Product Overview

The effectiveness of a hygienic process is only as good as the cleaning of the vessels. Our Sanitary Spray Balls automate the internal rinsing of storage tanks and reactors, reducing water consumption, chemical use, and downtime while ensuring every square centimeter of the vessel’s interior is sterilized.

Fixed vs. Rotary: Choosing the Right Impact

Depending on your product residue and tank size, we provide two distinct technologies:

-

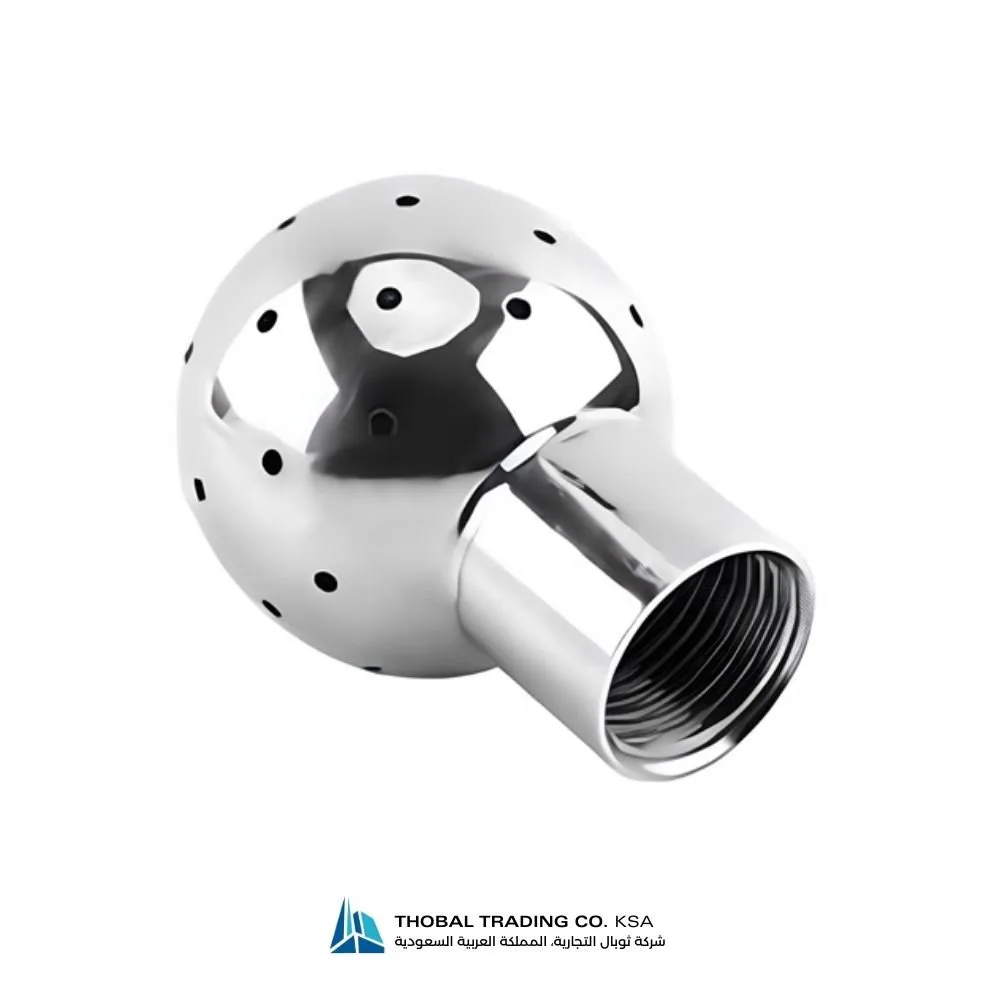

Fixed Spray Balls: Features a stationary spherical head with precision-drilled holes. These are ideal for “soaking” and low-impact rinsing of soluble residues. They are cost-effective, have no moving parts, and are highly reliable for standard dairy silos.

-

Rotary Spray Balls: Powered by the flow of the cleaning fluid, these heads rotate to provide dynamic, 360-degree spray coverage. The moving jets provide higher mechanical impact, making them the superior choice for stubborn residues like fats, proteins, or dry powders.

Engineered for Total Coverage

[Image showing the 360° spray pattern of a rotary cleaning head inside a tank] Our spray balls are designed to eliminate “dead spots.” The rotary versions use the fluid’s own energy to spin, ensuring that even the underside of agitator blades and the top dome of the tank receive a high-velocity wash. All units are polished to a mirror finish (Ra < 0.5μm) to ensure the cleaning head itself does not become a point of contamination.

Precision Standards

We stock spray balls in both DN (DIN) and SMS standards to integrate seamlessly with your existing pipework. Connection options include Clip-on (for easy removal), Threaded, or Butt-weld ends, ensuring a secure and hygienic attachment to your CIP supply line.