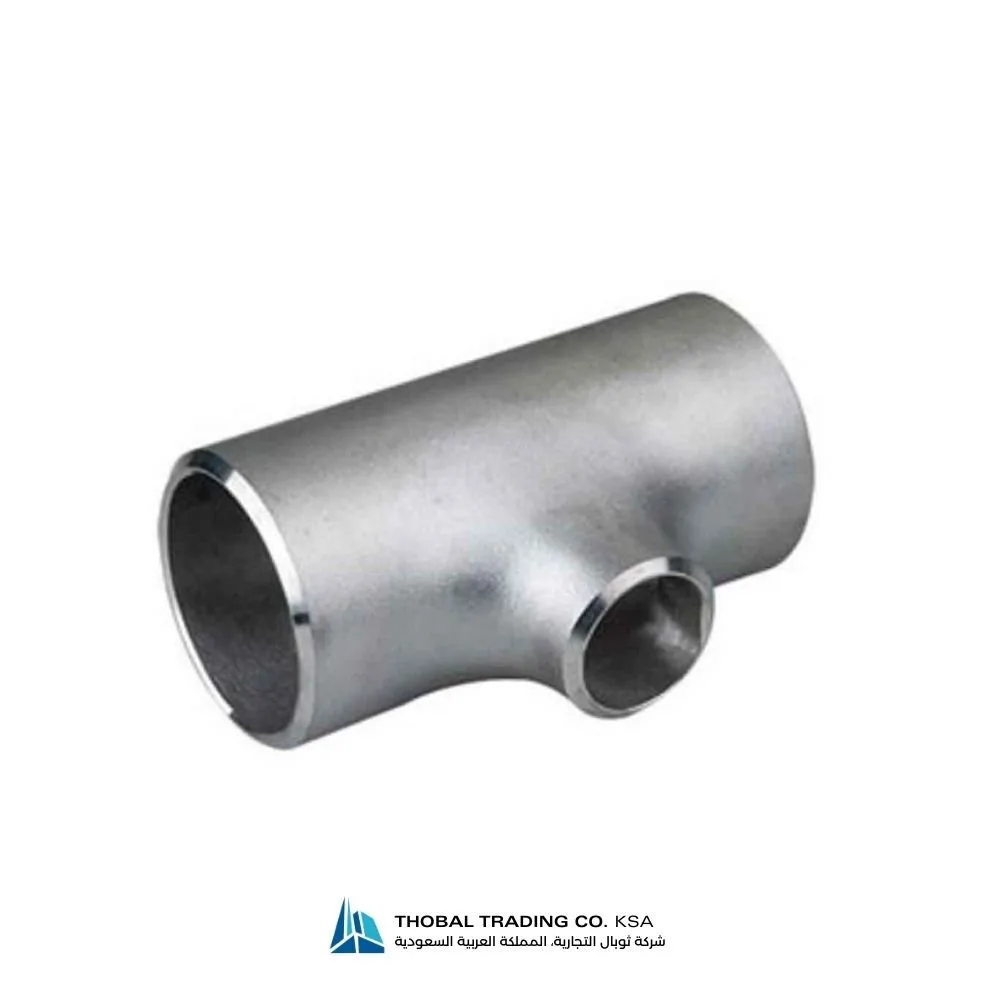

Product Overview

The Schedule Reducing Tee is a critical component in industrial piping architecture, allowing for the integration of smaller branch lines into a larger primary header. Unlike threaded fittings, these buttweld tees are designed for permanent installation, providing the maximum possible structural integrity at the junction point.

High-Strength Buttweld Integrity

Every tee is manufactured with precision-beveled ends to facilitate full-penetration welding. This creates a joint that is as strong as the pipe itself, making it the industry standard for high-pressure and high-temperature environments. By matching the wall thickness of Schedule 10 or Schedule 40 piping, our tees ensure a seamless transition without creating stress points.

Optimized Flow Dynamics

Our reducing tees are forged or formed to ensure smooth internal contours. This reduces turbulence and pressure drop at the branch point, which is essential for maintaining system efficiency and preventing erosion-corrosion. Whether you are branching off a small instrument line or a secondary process header, the internal geometry ensures consistent flow performance.

Material Excellence and Compliance

Fabricated from AISI 304L or 316L Stainless Steel, these fittings offer exceptional resistance to oxidation and corrosive chemical attack. The use of low-carbon grades (denoted by ‘L’) ensures that the fitting remains resistant to intergranular corrosion after the welding process. All units are fully compliant with ASME B16.9 and ASTM A403 specifications.