Product Overview

The Schedule Full Coupling is an essential straight-line connector used to bridge two pipe ends. Depending on your system requirements—whether you need the permanent strength of a weld or the convenience of a threaded joint—we offer this fitting in two distinct industrial configurations.

1. Buttweld Configuration (Permanent)

Designed for high-pressure and high-temperature environments, the buttweld variant features precision-beveled ends. When welded to Schedule 10 or Schedule 40 pipe, it creates a seamless, reinforced bridge that matches the pipe’s structural integrity. This is the preferred choice for petrochemical, steam, and hazardous chemical lines where leaks are not an option.

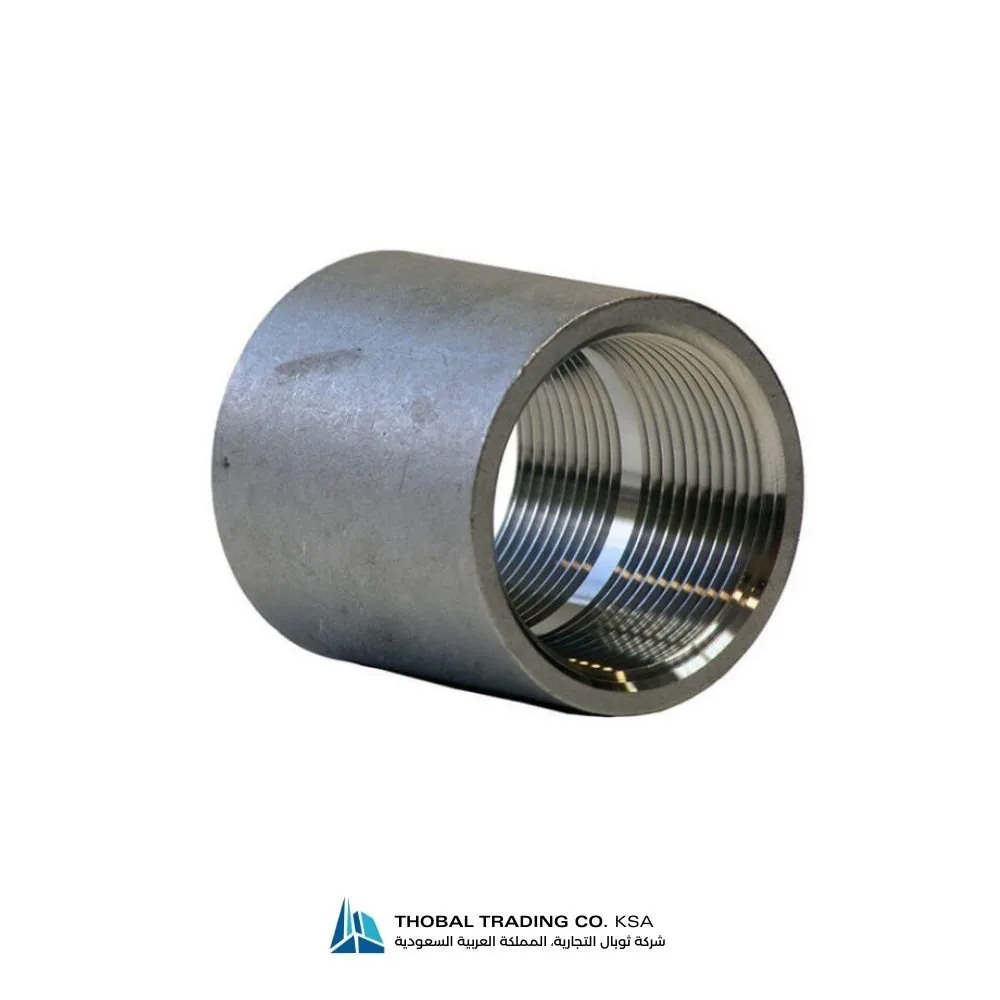

2. Threaded Configuration (Accessible)

For utility lines, compressed air, or systems that require frequent inspection and disassembly, our threaded couplings feature precision-machined NPT or BSP internal threads. These are rated for 150# or 3000# pressure classes and provide a secure mechanical seal without the need for hot work or welding permits.

Seamless Flow and Material Excellence

Both variants are machined to ensure the internal diameter (ID) matches your piping specifications, minimizing turbulence and erosion at the joint. Fabricated from AISI 304 or 316L Stainless Steel, they provide exceptional resistance to corrosion, oxidation, and chemical attack, ensuring long-term durability in harsh B2B environments.