Product Overview

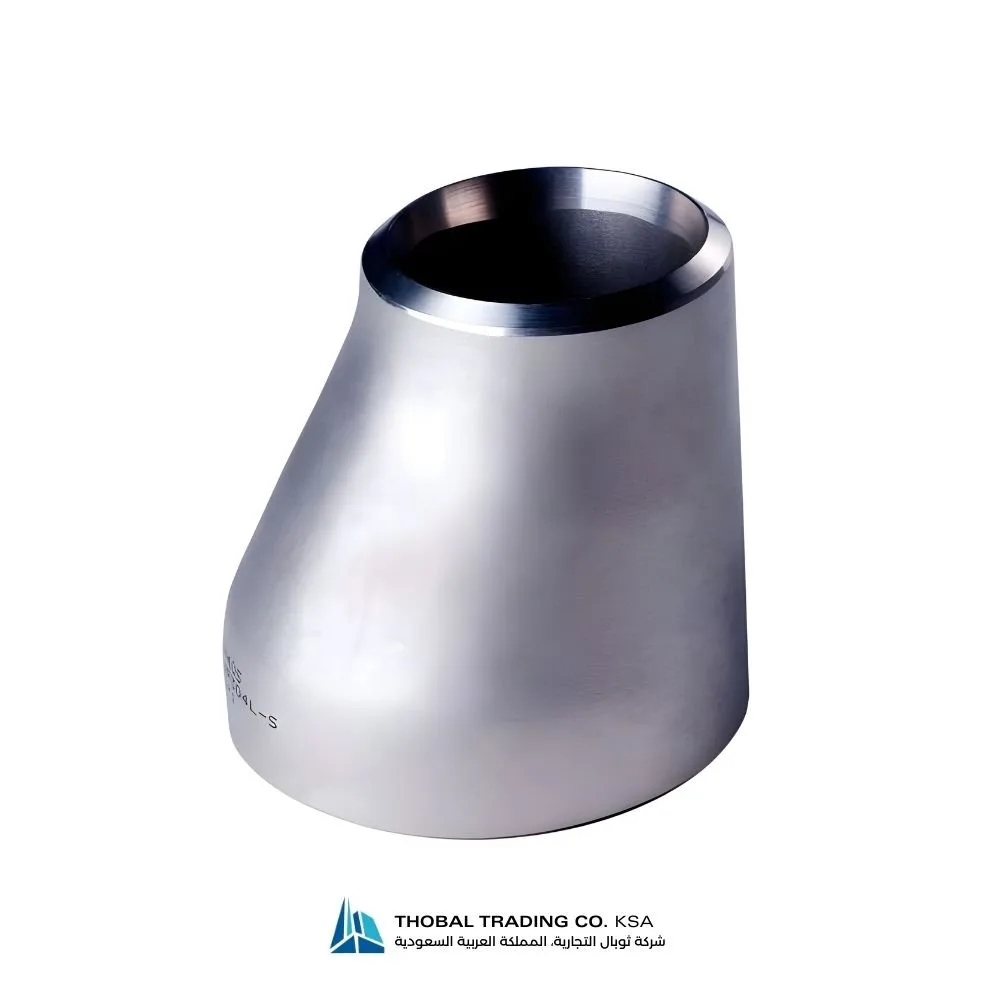

In industrial engineering, the Schedule Eccentric Reducer is a specialized buttweld fitting used to join pipes of different diameters where the center lines are not aligned. This “flat-on-one-side” design is essential for maintaining the flow characteristics and mechanical integrity of horizontal pipe runs.

Effective Air and Liquid Management

The primary advantage of an eccentric reducer is its ability to manage phase separation. When installed in horizontal lines with the flat side up, it prevents air or gas pockets from accumulating, which is critical in pump suction lines to avoid cavitation. Conversely, installing it flat-side down ensures complete liquid drainage, preventing stagnant “pockets” in the system.

Industrial-Strength Buttweld Integrity

Our reducers are manufactured with precision-beveled ends to ensure high-quality buttweld connections. These joints provide the strongest possible seal, matching the wall thickness and pressure ratings of your Schedule 10 (S10) or Schedule 40 (S40) stainless steel piping. This welded construction is designed to withstand significant thermal expansion, mechanical vibration, and high-pressure cycles common in B2B industrial environments.

Premium Material Construction

Fabricated from high-grade AISI 304 or 316L Stainless Steel, these fittings offer superior resistance to chemical corrosion and oxidation. The SS 316L variant, containing molybdenum, provides exceptional protection against chloride pitting, making it the preferred choice for petrochemical, marine, and aggressive chemical processing applications.