Product Overview

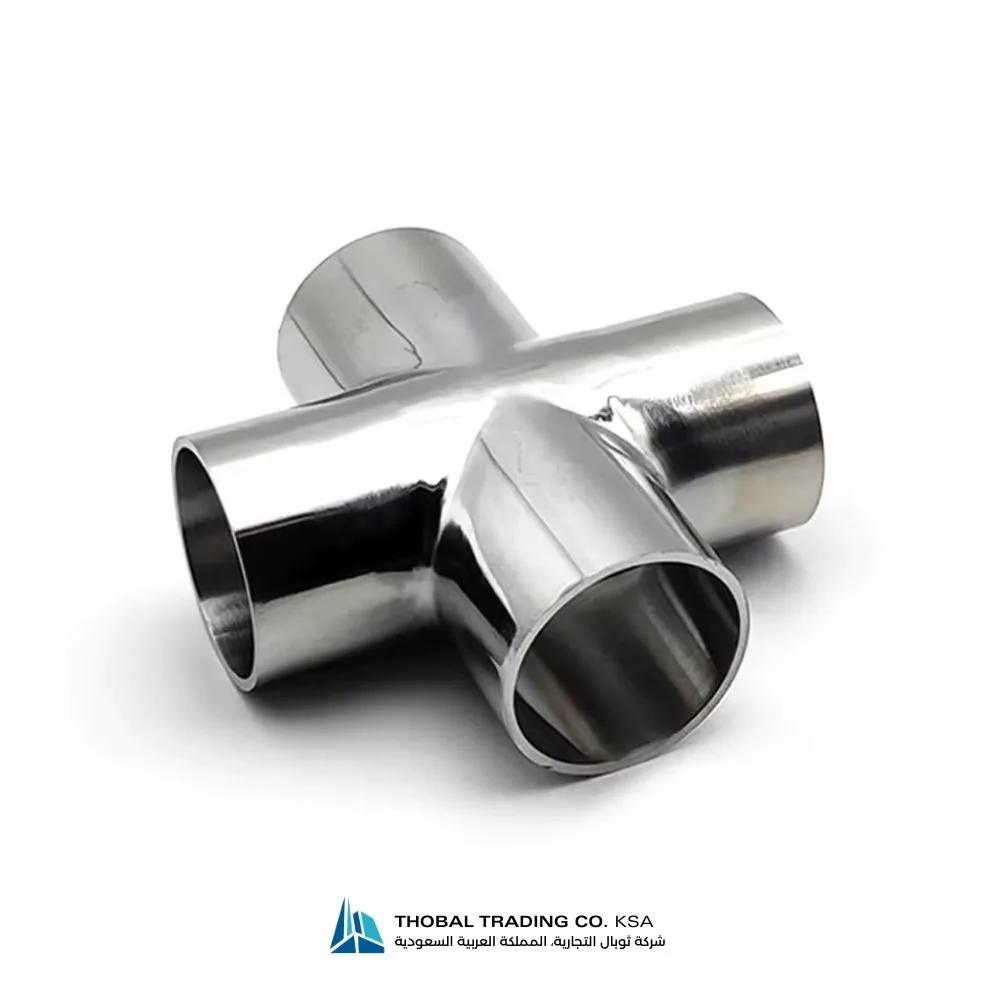

In advanced hygienic plant design, the Sanitary Cross is a critical component used to create intersection points or distribution hubs within a pipeline. Our crosses allow for the efficient branching of fluids in four directions while maintaining the strict cleanliness standards required in B2B sanitary applications.

Symmetrical Distribution and Flow Efficiency

The equal cross design ensures that fluid is distributed evenly across all branches. Engineered with a smooth internal radius, our crosses minimize turbulence and prevent “dead zones” where product could accumulate. This symmetrical geometry is essential for manifold systems where multiple lines must be fed or bled simultaneously.

Superior Hygienic Finish

Cleanliness is at the core of our manufacturing process. Each dairy cross is mechanically polished to a mirror finish, achieving an internal surface roughness of Ra < 0.8μm. This ultra-smooth surface eliminates microscopic crevices, making the fittings fully compatible with Clean-in-Place (CIP) and Steam-in-Place (SIP) procedures and ensuring your system remains sterile and compliant.

Material Integrity for High-Purity Lines

Constructed from AISI 304 or 316L Stainless Steel, these fittings are designed to withstand aggressive chemical cleaning agents and high-temperature processing. Fully compliant with SMS 1145 and DIN 11851 standards, they provide the dimensional accuracy and metallurgical reliability necessary for professional industrial fluid management.