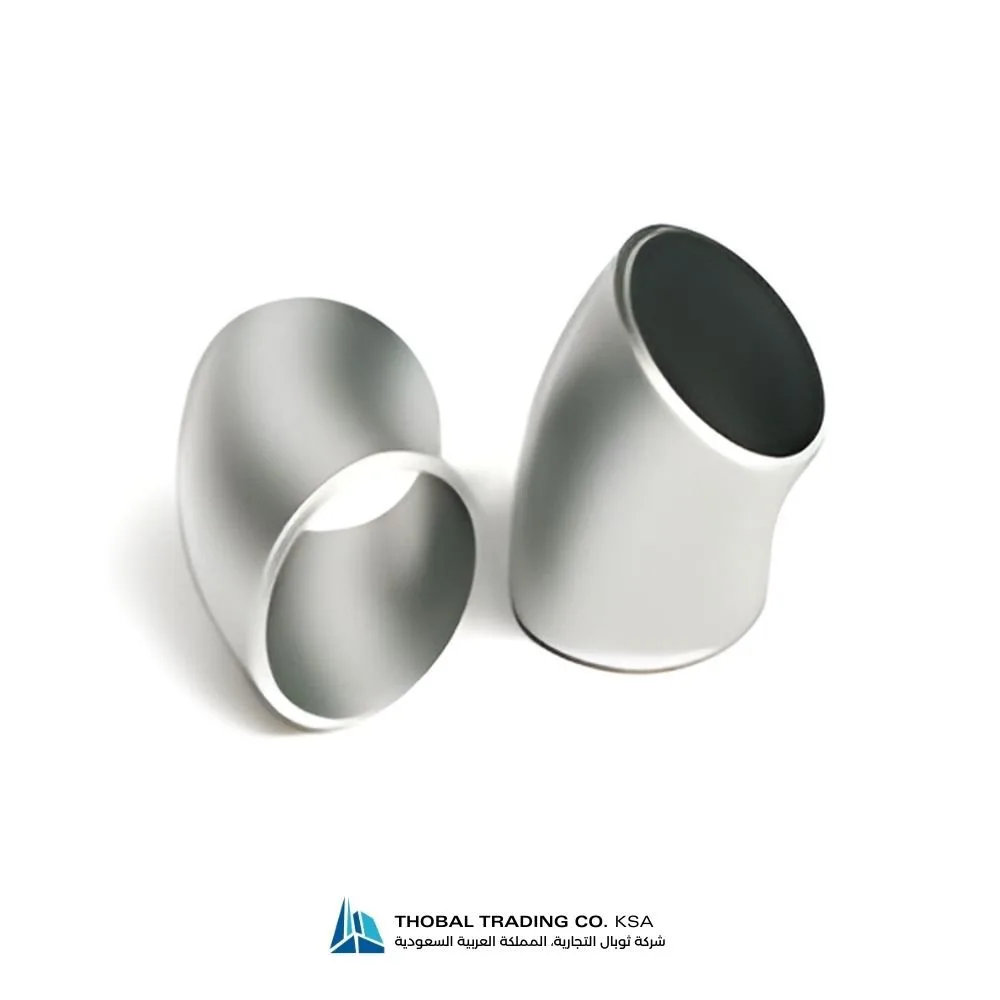

Product Overview

In industrial fluid dynamics, the 45 Degree Schedule Elbow is a vital component used to change the direction of a pipeline while minimizing internal friction. Unlike sharper bends, the 45-degree angle allows for efficient flow management in high-velocity or high-pressure systems.

Precision Buttweld Construction

These elbows are designed for buttweld connections, providing a permanent, leak-proof joint that is stronger than threaded or socket-weld alternatives. The ends are precision-beveled to ensure full penetration during the welding process, making them ideal for critical infrastructure where system failure is not an option.

Compliance with Global Standards

Our schedule elbows are manufactured in strict accordance with ASME B16.9 (factory-made wrought buttwelding fittings) and ASTM A403. This ensures that every fitting matches the wall thickness and pressure rating of your corresponding Schedule 10 or Schedule 40 stainless steel pipes, maintaining uniform strength throughout the network.

Material Performance for Harsh Environments

Utilizing premium AISI 316L and 304 Stainless Steel, these fittings are built to resist oxidation and chemical erosion. The 316L variant is particularly effective in marine or chemical environments due to its molybdenum content, which prevents pitting and stress corrosion cracking in extreme conditions.