Product Overview

The Schedule Half Coupling serves as a specialized “boss” or outlet fitting, designed to be welded onto the outer wall of a pipe or a pressure vessel. Unlike full couplings that join two pipes in a straight line, the half coupling provides a singular port—making it indispensable for adding secondary lines, drainage points, or monitoring equipment to a primary system.

Precision Dual-Configuration Design

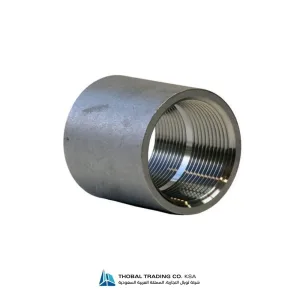

[Image showing a half coupling welded to a main header as a branch outlet] Depending on the specific industrial requirement, we provide these fittings in two primary styles:

-

Buttweld Half Couplings: Features a beveled end designed for deep-penetration welding. These are engineered to match the wall thickness of Schedule 10 and Schedule 40 pipes, ensuring that the branch point maintains the same pressure rating as the main line.

-

Threaded Half Couplings: Features precision-machined internal NPT or BSP threads. These allow for the direct, screw-in mounting of gauges, valves, or thermal sensors onto a welded base, providing a modular and accessible port.

Structural Integrity & Material Excellence

Constructed from forged or heavy-walled AISI 304 or 316L Stainless Steel, our half couplings are built to withstand high mechanical stress and thermal cycling. The low-carbon 316L variant is specifically recommended for corrosive chemical environments and high-purity water systems to ensure long-term resistance to oxidation and pitting at the weld zone.