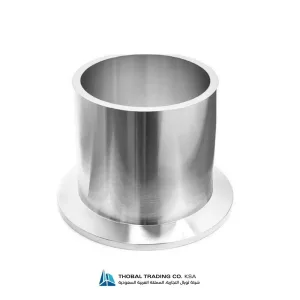

Product Overview

A Hygienic Union End Cap is a specialized termination fitting used to seal off a male-threaded union part. Unlike a standard pipe cap, these are designed to be used in high-purity systems where regular dismantling for cleaning or system expansion is necessary. They provide a flush, hygienic seal that prevents product stagnation at the end of a header.

Aseptic Termination & Safety

In a hygienic process, any unused port must be sealed to maintain system pressure and sterility. Our union caps utilize a solid Blanking Disc (Liner) that sits against the male union part. When the nut is tightened, it compresses the gasket to create an airtight, metal-to-metal reinforced seal. The design ensures there are no crevices or “dead legs,” making it fully compatible with Clean-in-Place (CIP) protocols.

Precision Standards for Global Systems

We offer blanking solutions for the two most common international hygienic union standards:

-

SMS Standard: Featuring a flat-faced blanking disc, commonly used in beverage and liquid food manifolds.

-

DIN 11851 Standard: Featuring a heavy-duty blanking liner with a characteristic profile, widely used in European pharmaceutical and chemical process skids.

Superior Metallurgy and Surface Finish

Constructed from AISI 316L Stainless Steel, these caps offer maximum resistance to corrosion and chemical sanitizers. All wetted surfaces are mirror-polished to Ra < 0.6μm, ensuring the fitting remains free of bacterial harbor points and is easy to sterilize during Steam-in-Place (SIP) cycles.